“Ending the Era of Greasy Drains and Fatberg-Induced Clogs”

BUPYEONG-GU, INCHEON, SOUTH KOREA, February 22, 2026 /EINPresswire.com/ — Daeshin MC announced a transformative proposal to address one of the most persistent operational risks in the foodservice and franchise industry: grease-related sewer blockages in restaurant kitchens. By introducing its compact oil-water separator, the DS-2040, the company seeks to shift kitchen wastewater management from reactive maintenance to proactive structural prevention.

The problem is neither new nor isolated. In fast-food restaurants, where high-volume patty grilling, frying, and dishwashing take place daily, grease-related sewer issues have become routine. Unlike used fryer oil, which is already managed through collection programs, oils produced during patty cooking, as well as milk fat and sugar residues from beverages, flow directly into the drain during dishwashing. Over time, these residues accumulate unseen within sewer lines, forming fatbergs that cause foul odors, backflow, and ultimately complete blockages. The issue affects restaurants across the industry and has become a source of operational disruption, financial burden, and friction with building owners.

What was once viewed as a matter of individual store management has now escalated into a system-wide challenge. Emergency drain-clearing costs frequently exceed hundreds of thousands of won per incident, and repeated interventions can interrupt kitchen workflows or even force temporary closures. As the number of franchise locations increases, these cumulative costs shift from individual stores to corporate headquarters. Recent commercial building contracts now commonly include explicit clauses assigning responsibility for sewer blockages, with many specifying the installation of oil-water separation equipment as a mandatory condition.

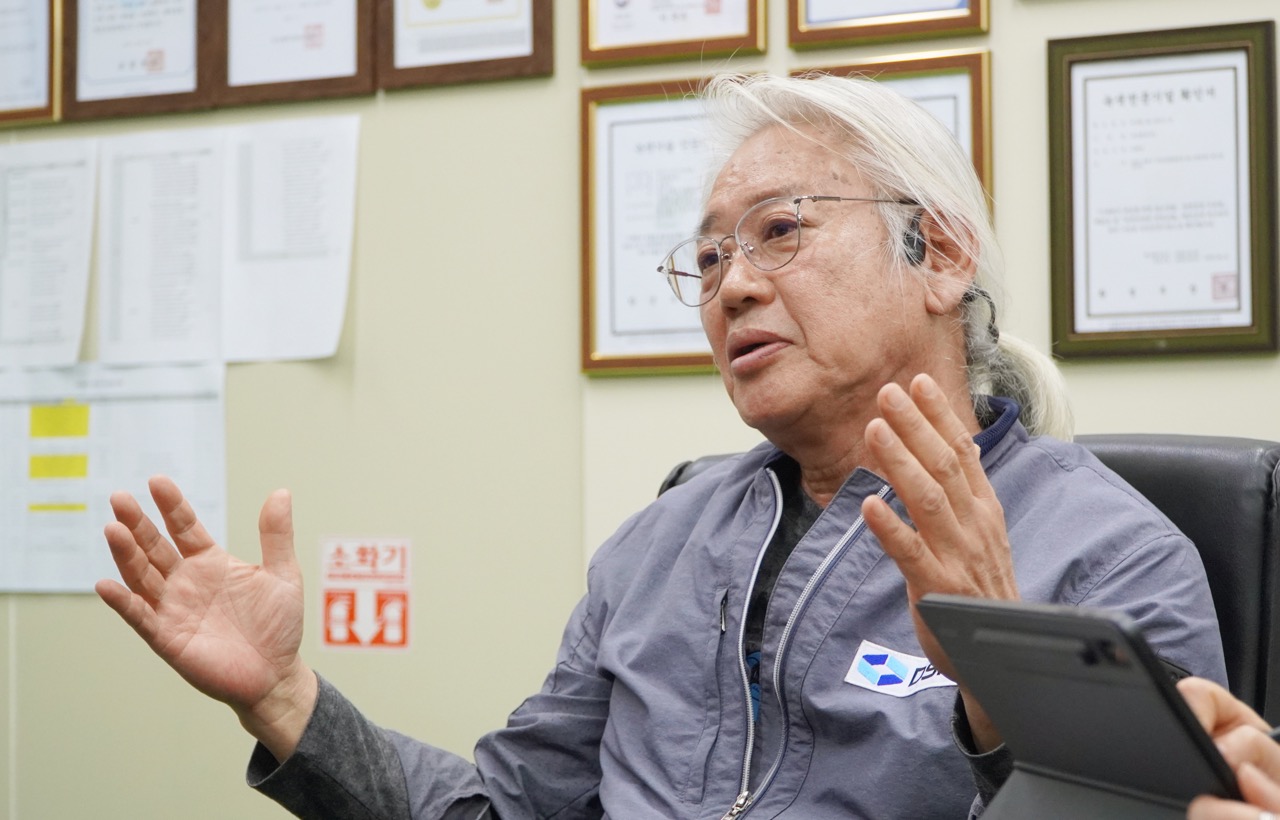

Daeshin MC CEO Younghwan Choi describes this mounting issue as “a structural risk in the kitchen hidden behind a glamorous dining hall.” After years of supplying industrial-scale oil-water separation systems to major factories, cafeterias, and public sites, the company turned its attention to franchise environments. Choi and his team found that the most pressing problems originated not in large manufacturing facilities but in restaurant kitchens—particularly hamburger chains—where oil from dishwashing wastewater remains unmanaged at its source.

To address this systemic challenge, Daeshin MC developed the DS-2040, a compact oil-water separator designed for installation directly beneath the kitchen sink. The unit intercepts dishwashing wastewater before it enters the sewer line and separates oil using only natural gravity and density differences, requiring no electricity or sensors. Oil accumulates within the unit while only water flows downstream, preventing grease deposits and eliminating the root cause of drain blockages without altering kitchen workflows.

The company has already proven the reliability of its technology at high-load industrial sites, including the Paldo Ramyeon factory in Naju, POSCO cafeterias, and military submarine facilities. In small-business settings, earlier compact models have demonstrated effective long-term performance by significantly reducing drain clogs and odors. Leveraging these field results, Daeshin MC refined and standardized the DS-2040 specifically for franchise deployment.

In addition to operational relief, the DS-2040 enables a new model for environmental performance. By converting recovered oil—previously discharged as wastewater—into a measurable ESG resource, Daeshin MC proposes a system that enables restaurants to track and manage oil recovery, potentially benefiting from refund structures based on the amount collected. The company emphasizes that what once generated recurring disposal costs can now contribute to ESG reporting and resource circulation initiatives. With many stores able to recoup installation costs through reduced emergency maintenance alone, the equipment becomes a strategic management tool rather than a simple operational expense.

Daeshin MC positions the DS-2040 not as optional equipment for individual small business owners but as essential infrastructure for modern franchise systems. As global brands accelerate ESG commitments and regulators increasingly focus on wastewater and resource recovery, the company argues that structural improvements beneath the kitchen—long overlooked—will determine the next stage of sustainable restaurant operations. By eliminating sewer risk, supporting environmental management, and strengthening cost efficiency, the DS-2040 offers a practical foundation for franchises seeking to modernize their operations in line with global standards.

For Daeshin MC, the proposal marks a broader shift: from treating grease-induced drain issues as isolated incidents to recognizing them as solvable structural challenges. The company asserts that the future of restaurant sustainability and stability begins not in the dining hall but under the kitchen sink.

Yoona Choi

Daeshin MC

+82 32-511-5001

email us here

Visit us on social media:

LinkedIn

YouTube

Other

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()